WATER-Water Heat Exchangers Series K30, K45

Price 100-300000 INR/ Unit

WATER-Water Heat Exchangers Series K30, K45 Specification

- Application

- Water to Water Heat Exchange, Cooling Systems, Water Heating Systems

- Load Capacity

- Up to system design specifications

- Connectivity Type

- Piping Connection

- Mounting Type

- Horizontal or Vertical

- Weight

- Varies by model (Contact supplier)

- Control Type

- Manual

- Automation Grade

- Manual

- Temperature

- Up to 100C (212F)

WATER-Water Heat Exchangers Series K30, K45 Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About WATER-Water Heat Exchangers Series K30, K45

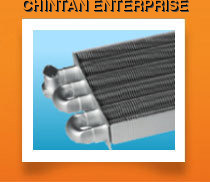

WATER-Water Heat Exchangers Series K30, K45

| SCAMBIATORI DI CALORE ACQUA-ACQUA. SERIE K30, K45 |

| MAIN CHARACTERISTICS : These are fast heat exchangers for combined boilers for central heating and domestic hot water. They contain a copper coil wrapped in a series of concentric spirals with different diameters. The primary circuit is connected to the heating circuit and consists of a series of cylindrical baffles that force water to make multiple vertical passes in order to efficiently move along the outer surface of the copper tube. Both internal circuits are welded to threaded connection to permit installation of the heat exchanger in the plumbing circuit. |

MATERIALS

|

Durable Construction for Reliable Performance

Series K30 and K45 heat exchangers boast mild steel shells coated with epoxy paint, ensuring excellent corrosion resistance and long-term durability. Their robust design makes them ideal for various water heating and cooling applications, whether used in industrial, commercial, or residential systems.

Efficient Heat Transfer and Flexible Operation

Both models are engineered for optimal thermal exchange, with tube arrangements designed for maximum surface contact and efficiency. The flexibility of flanged or threaded connections, combined with compatibility for water and glycol solutions, ensures seamless integration into different piping systems and satisfied operational needs.

FAQs of WATER-Water Heat Exchangers Series K30, K45:

Q: How do I install the Series K30 or K45 Water Heat Exchanger?

A: Installation involves connecting the inlet and outlet ports to your system piping using either flanged or threaded connections. You can mount the unit horizontally or vertically, according to your available space and design requirements. Manual control allows for straightforward operational adjustments.Q: What maintenance is required for these heat exchangers?

A: Routine maintenance is minimal, as the design offers easy access for cleaning. Periodically inspect and clean the tubes and shell to remove any buildup, ensuring sustained heat transfer and extending the life of your system.Q: When should I choose between the K30 and K45 models?

A: Select the K30 if your application requires a heat transfer area up to 1.0 m, suitable for smaller systems. Opt for the K45 model when you need a larger area (approximately 1.5 m), ideal for more intensive heating or cooling operations.Q: Where can these heat exchangers be used?

A: These models are suitable for water-to-water heat exchange in cooling systems, water heating systems, and any process requiring controlled thermal transfer. They are designed to integrate with various system configurations in industrial, commercial, and residential settings.Q: What fluids are compatible with the Series K30 and K45 heat exchangers?

A: Both models are compatible with water and glycol solutions, making them versatile options for many heating and cooling applications. Always confirm fluid compatibility for your specific use-case with your supplier.Q: How does the manual control benefit operation?

A: Manual control offers users direct handling over the operation, making adjustments quick and easy. This simplicity is ideal for systems where automatic controls are not needed, further lowering maintenance and operational complexities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

GAS-Water Heat Exchangers Series SM50

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Hot Water Generation, District Heating, Food Industries, Chemical Industries

Mounting Type : Floor/Wall Mounted

Temperature : Up to 300C

Material : Stainless Steel

WATER-Water Heat Exchangers Series KP20, KP24

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Water To Water Heat Exchanger; HVAC, Industrial Heating and Cooling

Mounting Type : Floor Mounted / Skid Mounted

Temperature : Max Operating Temperature: 150C

Material : Stainless Steel / Mild Steel

GAS-Water Heat Exchangers Series SM4C

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial heating, Swimming pools, Food & Beverage, HVAC

Mounting Type : Horizontal / Vertical

Temperature : Up to 150C

Material : Stainless Steel

Heat Exchangers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Pharmaceutical, Chemical, Food & Beverage Industry

Mounting Type : Horizontal/Vertical

Temperature : Up to 150C

Material : Stainless Steel

Send Inquiry

Send Inquiry