GAS-Water Heat Exchangers Series SM50

Price 100-300000 INR/ Unit

GAS-Water Heat Exchangers Series SM50 Specification

- Remote Control

- Yes

- Weight

- Approx. 40 kg

- Frequency

- 50 Hz

- Phase

- Single Phase

- Control Type

- Digital

- Mounting Type

- Floor/Wall Mounted

- Connectivity Type

- Wired

- Sensor Type

- Temperature Sensor

- Drive Type

- Direct

- IP Rating

- IP54

- Application

- Hot Water Generation, District Heating, Food Industries, Chemical Industries

- Cable Length

- 2 meters

- Automation Grade

- Automatic

- Material

- Stainless Steel

- Power

- 50 kW

- Temperature

- Up to 300C

- Voltage

- 230 V

- Inlet/Outlet Connection

- 2 inch BSP

- Safety Features

- Overheat Protection, Pressure Relief Valve

- Dimensions

- 900 mm x 500 mm x 400 mm

- Heat Exchanger Type

- Shell and Tube

- Surface Finish

- Polished

- Working Pressure

- Up to 10 bar

- Capacity

- 50,000 kcal/hr

- Max Water Flow Rate

- 2.5 m³/h

- Lifespan

- 15+ years (under recommended conditions)

GAS-Water Heat Exchangers Series SM50 Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About GAS-Water Heat Exchangers Series SM50

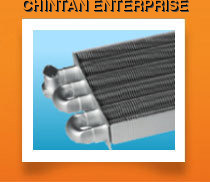

GAS-Water Heat Exchangers Series SM50

| SCAMBIATORI DI CALORE GAS - ACQUA. SERIE SM 50 |

| MAIN CHARACTERISTICS : Primary heat exchanger for domestic gas-fired boilers with oval shaped tubes. The heat exchange surface is made entirely out of copper. This achieves very high efficiency rates as required by current standards for high performance heat exchangers. Tabulators are installed inside the water tubes to increase heat exchange coefficients. Fins are braze-welded to the tubes. Heat exchanger surface are suitably protected against corrosion by a surface treatment patented by MUT. The 5- tube version permits the two connection fittings to be on opposite sides. |

MATERIALS

|

Exceptional Performance and Safety

The Series SM50 heat exchanger delivers consistent efficiency, supporting operating temperatures up to 300C and pressures reaching 10 bar, making it ideal for industrial heating tasks. Safety measuresincluding built-in overheat protection and a pressure relief valvesafeguard users and equipment, promoting operational peace of mind while optimally managing hot water generation.

Versatile Applications and Easy Installation

This heat exchanger caters to diverse sectors such as hot water generation, district heating, food processing, and chemical industries. Featuring a compact design (900 mm x 500 mm x 400 mm) and flexible mounting, either on the floor or wall, installation is straightforward. The wired connectivity and automatic digital controls make integration with existing systems simple and efficient.

FAQs of GAS-Water Heat Exchangers Series SM50:

Q: How is the GAS-Water Heat Exchangers Series SM50 installed?

A: Installation can be done on either the floor or wall, utilizing its compact size and the 2-inch BSP inlet/outlet connections. Detailed instructions are supplied to ensure secure mounting and appropriate electrical wiring for the 230 V single-phase power requirement.Q: What industries are suitable for deploying the SM50 Series heat exchanger?

A: This model is ideal for applications in district heating, hot water generation, food processing, and chemical industries due to its robust stainless steel construction, high capacity, and reliable automation features.Q: When should the heat exchangers safety features be checked or maintained?

A: Regular inspection of overheat protection and the pressure relief valve are recommended during routine maintenance intervals to guarantee optimal functionality and safety, ensuring continued reliability over its expected 15+ year lifespan.Q: Where can I purchase the Series SM50 heat exchanger in India?

A: You can obtain this model from authorized distributors, exporters, importers, manufacturers, or traders across India, which ensures you receive genuine products and after-sales support.Q: What is the process for connecting the unit to existing piping and power supply?

A: Connect the water lines using the standard 2-inch BSP fittings and secure the unit to the designated power supply (230 V, single phase) with the provided 2-meter cable. Ensure connections are leak-free and compliant with local regulations before operation.Q: How does the automatic control system benefit daily operation?

A: The integrated digital control and temperature sensors automate regulation of temperature and flow rates, enhancing energy efficiency and minimizing manual intervention. Wired connectivity streamlines monitoring and arrangement adjustments without requiring remote controls.Q: What advantages does using the SM50 heat exchanger offer?

A: Key benefits include reliable high-capacity performance, polished stainless steel durability, long lifespan, effective safety features, and suitability for various industries. Its automated control, direct drive, and easy connection enable smooth integration and minimal operational hassle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

WATER-Water Heat Exchangers Series KP20, KP24

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Water To Water Heat Exchanger; HVAC, Industrial Heating and Cooling

Load Capacity : Varies By Model

Temperature : Max Operating Temperature: 150C

Mounting Type : Floor Mounted / Skid Mounted

GAS-Water Heat Exchangers Series SM4C

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial heating, Swimming pools, Food & Beverage, HVAC

Load Capacity : Up to 20 bar

Temperature : Up to 150C

Mounting Type : Horizontal / Vertical

Heat Exchangers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Pharmaceutical, Chemical, Food & Beverage Industry

Load Capacity : Varies as per model

Temperature : Up to 150C

Mounting Type : Horizontal/Vertical

WATER-Water Heat Exchangers Series K

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial, Chemical, HVAC, Water Cooling/Heating

Load Capacity : Up to 10000 LPH (Litres Per Hour)

Temperature : Up to 150C

Mounting Type : Horizontal / Vertical

Send Inquiry

Send Inquiry