WATER-Water Heat Exchangers Series KP20, KP24

Price 100-300000 INR/ Unit

WATER-Water Heat Exchangers Series KP20, KP24 Specification

- Frequency

- 50/60 Hz

- Cable Length

- Custom As Per Requirement

- Control Type

- Manual

- Mounting Type

- Floor Mounted / Skid Mounted

- Weight

- Approximately 55 kg (KP20), 85 kg (KP24)

- Load Capacity

- Varies By Model

- Connectivity Type

- Flanged / Threaded Connections

- Phase

- Three Phase

- Drive Type

- Direct

- Application

- Water To Water Heat Exchanger; HVAC, Industrial Heating and Cooling

- Speed Range

- Fixed

- IP Rating

- IP55

- Material

- Stainless Steel / Mild Steel

- Power

- Up to 250 kW

- Temperature

- Max Operating Temperature: 150C

- Voltage

- 415 V AC

- Heat Transfer Area

- Up to 6 m²

- Model

- KP20, KP24

- Tube Material

- Copper / Stainless Steel

- Shell Diameter

- 200 mm (KP20), 240 mm (KP24)

- Tube Diameter

- 16 mm

- Number of Passes

- 2 Pass / 4 Pass Options

- Design Pressure

- 6 bar

WATER-Water Heat Exchangers Series KP20, KP24 Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About WATER-Water Heat Exchangers Series KP20, KP24

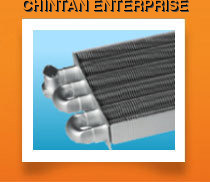

WATER-Water Heat Exchangers Series KP20, KP24

| MAIN CHARACTERISTICS : These heat exchangers are made for use in combined domestic boilers with rapid heating of domestic hot water. This water runs inside a copper coil wrapped in three concentric spirals with different diameters. The primary circuit is connected to the heating circuit and consists of a series of cylindrical baffles that force water to make multiple vertical passes in order to efficiently move against the outer surface of the copper tube. Both internal circuits are welded to threaded connections for installing the heat exchanger in the plumbing circuit. These is also a version for direct connection with a diverter valve for interchanging fluid flow when there is a request for domestic hot water. These units differ from K series because of their compact vertical dimensions that permit better exploitation of the space inside the boiler. |

MATERIALS

|

Key Features and Construction

KP20 and KP24 heat exchangers stand out with their durable build and performance versatility. Their shell diameters (KP20: 200 mm; KP24: 240 mm), tube materials, and design pressure make them suitable for demanding applications. IP55 protection and manual control add reliability, while three-phase operation at 415V AC supports robust industrial setups.

Applications and Versatility

These heat exchangers excel in water-to-water systems for HVAC, industrial heating, and cooling. Their adaptability for both floor-mounted and skid-mounted installations supports a range of operational needs in factories, commercial buildings, and technical environments across India.

Advantages of Series KP20, KP24

Users benefit from high thermal efficiency, flexible installation, and compatibility with custom cable lengths and connection types. The models are engineered for easy integration, providing consistent temperature regulation and energy savings in various operational contexts.

FAQs of WATER-Water Heat Exchangers Series KP20, KP24:

Q: How do I select between the KP20 and KP24 heat exchanger models?

A: Model selection primarily depends on your required heat transfer area and space availability. KP20 offers a 200 mm shell diameter at approximately 55 kg, while KP24 provides a larger 240 mm shell and weighs around 85 kg, supporting increased capacity.Q: What is the process of installing the KP20 or KP24 heat exchanger?

A: Installation involves securing the unit using floor or skid mounts, connecting piping via flanged or threaded connections, and wiring for three-phase power (415V AC). Ensure the system operates within the specified pressure (up to 6 bar) and temperature (max 150C) limits.Q: Where are these heat exchangers commonly used?

A: KP20 and KP24 models are widely implemented in water-to-water solutions for HVAC, industrial heating and cooling, and similar applications within manufacturing facilities, commercial buildings, and technical plants.Q: What are the benefits of choosing copper or stainless-steel tubes?

A: Copper tubes offer excellent thermal conductivity and corrosion resistance, ideal for efficient heat transfer. Stainless steel tubes provide added durability and are suitable for environments requiring higher resistance against aggressive fluids or conditions.Q: When should I opt for a 2-pass versus a 4-pass configuration?

A: A 2-pass option is suitable for standard heat exchange requirements; select a 4-pass configuration for enhanced heat transfer performance or where greater temperature differentials are needed between water circuits.Q: How does the manual control type work in these exchangers?

A: Manual control allows operators to directly manage operating parameters, such as start/stop and process adjustments, enhancing on-site reliability and responsiveness to operational changes.Q: What advantages does the IP55 rating provide?

A: IP55 protection shields the heat exchanger from dust ingress and water jets, ensuring safe and reliable operation even in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

GAS-Water Heat Exchangers Series SM50

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Hot Water Generation, District Heating, Food Industries, Chemical Industries

Temperature : Up to 300C

Mounting Type : Floor/Wall Mounted

Control Type : Digital

GAS-Water Heat Exchangers Series SM4C

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial heating, Swimming pools, Food & Beverage, HVAC

Temperature : Up to 150C

Mounting Type : Horizontal / Vertical

Control Type : Electronic / Manual

Heat Exchangers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Pharmaceutical, Chemical, Food & Beverage Industry

Temperature : Up to 150C

Mounting Type : Horizontal/Vertical

Control Type : Manual

WATER-Water Heat Exchangers Series K

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial, Chemical, HVAC, Water Cooling/Heating

Temperature : Up to 150C

Mounting Type : Horizontal / Vertical

Control Type : Manual

Send Inquiry

Send Inquiry