Heat Exchangers

Price 100-300000 INR/ Unit

Heat Exchangers Specification

- Phase

- Single Phase

- Frequency

- 50 Hz

- IP Rating

- IP54

- Mounting Type

- Horizontal/Vertical

- Application

- Pharmaceutical, Chemical, Food & Beverage Industry

- Remote Control

- Yes

- Automation Grade

- Manual

- Control Type

- Manual

- Load Capacity

- Varies as per model

- Material

- Stainless Steel

- Power

- 220 W

- Temperature

- Up to 150C

- Voltage

- 220 V

- Tube Diameter

- 12.7 mm or custom

- Surface Finish

- Polished

- Working Pressure

- Up to 10 bar

- Type

- Shell and Tube / Plate Type

- Flow Rate

- Up to 2000 LPH

- End Connection

- Flanged / Threaded / Custom

Heat Exchangers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Heat Exchangers

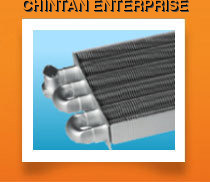

Empowered with the correct combination of an expert workforce and modern machinery, we are able to supply and export Heat Exchangers. These products are made of superior quality raw materials at our vendors end. With effective heat exchanging, these products provide accurate performance. Our clients appreciate these products for their correct functionality and better workability. Heat Exchangers are available with us in different specifications as per the requirements of the clients.

Versatile Heat Exchange Solutions

Tailored for a wide range of process industries, our heat exchangers combine high performance, reliability, and flexibility. With manual automation and various mounting options, these units integrate seamlessly into pharmaceutical, chemical, and food & beverage operations. Available through distributors, manufacturers, and traders, each model adapts to unique process requirements.

Durable Construction and Efficient Performance

Manufactured from premium stainless steel with a polished finish, our heat exchangers deliver robust durability and optimized thermal transfer. Supporting custom tube diameters and end connections, they sustain efficient heat exchange, operate at temperatures up to 150C, and assure safety with an IP54 rating. They excel in environments demanding precise, controlled operation.

FAQs of Heat Exchangers:

Q: How do I select between shell and tube and plate type heat exchangers for my application?

A: Selection depends on your process requirements. Shell and tube exchangers are ideal for higher pressures and larger flow rates, while plate type exchangers offer compactness and efficient heat transfer for lower flow rates or more space-restricted installations.Q: What is the recommended process for installation and mounting of these heat exchangers?

A: Install the unit on a horizontal or vertical mount, depending on space constraints and flow direction. Ensure proper alignment of flanged or threaded connections and verify compliance with local industrial safety standards before commissioning.Q: When should the heat exchanger be inspected or maintained?

A: Routine inspection is advisable every 6 to 12 months, especially in demanding environments such as chemical or pharmaceutical processing. Maintenance includes cleaning surfaces, checking seals, and ensuring manual controls and connections remain secure.Q: Where are these heat exchangers commonly used?

A: These models are primarily deployed in pharmaceutical, chemical, and food & beverage industries across India, as they handle stringent process controls and varying temperatures demanded by these sectors.Q: What benefits do heat exchangers with polished stainless steel and customizable features provide?

A: A polished stainless steel surface offers superior corrosion resistance and easier cleaning for sanitary requirements. Customizable tube diameters and end connections enable integration into diverse process lines, maximizing operational efficiency.Q: How is the flow rate and working pressure managed with manual control systems?

A: Manual control permits operators to adjust flow and pressure parameters in real-time, allowing flexible process management while maintaining operational safety and quality. Clear indicators and accessible controls facilitate precise handling even without remote automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

GAS-Water Heat Exchangers Series SM50

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 300C

Control Type : Digital

Mounting Type : Floor/Wall Mounted

Application : Hot Water Generation, District Heating, Food Industries, Chemical Industries

WATER-Water Heat Exchangers Series KP20, KP24

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Max Operating Temperature: 150C

Control Type : Manual

Mounting Type : Floor Mounted / Skid Mounted

Application : Water To Water Heat Exchanger; HVAC, Industrial Heating and Cooling

GAS-Water Heat Exchangers Series SM4C

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 150C

Control Type : Electronic / Manual

Mounting Type : Horizontal / Vertical

Application : Industrial heating, Swimming pools, Food & Beverage, HVAC

WATER-Water Heat Exchangers Series K

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 150C

Control Type : Manual

Mounting Type : Horizontal / Vertical

Application : Industrial, Chemical, HVAC, Water Cooling/Heating

Send Inquiry

Send Inquiry