GAS-Water Heat Exchangers Series SM4C

Price 100-300000 INR/ Unit

GAS-Water Heat Exchangers Series SM4C Specification

- Application

- Industrial heating, Swimming pools, Food & Beverage, HVAC

- Remote Control

- Yes

- IP Rating

- IP55

- Automation Grade

- Automatic

- Mounting Type

- Horizontal / Vertical

- Phase

- Single / Three Phase

- Frequency

- 50/60 Hz

- Control Type

- Electronic / Manual

- Cable Length

- Custom as required

- Connectivity Type

- Flanged / Threaded Connections

- Load Capacity

- Up to 20 bar

- Material

- Stainless Steel

- Temperature

- Up to 150C

- Voltage

- 230V / 415V AC

GAS-Water Heat Exchangers Series SM4C Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About GAS-Water Heat Exchangers Series SM4C

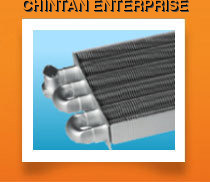

GAS-Water Heat Exchangers Series SM4C

| SCAMBIATORI DI CALORE ACQUA-ACQUA. SERIE K30, K45 |

| MAIN CHARACTERISTICS : Primary heat exchanger for domestic gas-fired boilers. The heat exchangers surface is made entirely of copper and can achieve very high valves of efficiency as required by existing standards for high-performance heat exchangers. Tabulators are installed inside the water tubes to increase heat exchange coefficients. Fins are braze- welded to the tubes. Heat exchanger surface are suitably protected against corrosion by a surface treatment patented by MUT. The 4 tube version allows the possibility of both fittings to be on the same side of the heat exchanger. |

MATERIALS

|

Advanced Design and Versatility

The Series SM4C heat exchangers stand out with their shell-and-tube coil construction, making them ideal for industrial heating, pools, HVAC, and food & beverage processing. Models suit different environmental requirements through automatic or manual control, horizontal or vertical mounting, and compatibility with both flanged and threaded pipework. Stainless steel construction ensures durability while the polished or matt finish offers aesthetic and corrosion resistance.

Robust Performance and Safety

With capacity up to 800,000 Kcal/hr and maximum working pressure of 20 bar, these exchangers meet IS and ASME standards for safety and performance. Operating reliably up to 150C, they are protected with an IP55 rating and can be seamlessly integrated into various industrial systems. Customized cable lengths and control configurations further enhance safety and ease of use.

FAQs of GAS-Water Heat Exchangers Series SM4C:

Q: How do I select the correct capacity for my application using the SM4C heat exchanger series?

A: To select the right capacity, determine your systems heat load requirement and match it with the SM4Cs capacity range, which goes up to 800,000 Kcal/hr. Consider factors like operating pressure, inlet/outlet sizes, and compatibility with your application, whether it is industrial heating, swimming pools, or HVAC.Q: What is the process for installing a GAS-Water Heat Exchanger SM4C?

A: Installation involves positioning the unit horizontally or vertically based on your setup, connecting the inlet/outlet through flanged or threaded connections (DN25 to DN100), and ensuring all controls and electrical connections (230V/415V AC, single or three phase) are securely fitted as per IS or ASME standards.Q: Where can the SM4C Series heat exchangers be used efficiently?

A: These exchangers are suitable for industrial heating, swimming pools, food & beverage processing, and HVAC projects, offering robust performance and compliance for various operational conditions within India and for export requirements.Q: What benefits does the stainless steel shell-and-tube design provide?

A: Stainless steel construction provides high corrosion resistance, durability, and hygiene, while the shell-and-tube design ensures efficient heat transfer and ease of cleaningessential for food, beverage, and demanding industrial applications.Q: When should the exchangers automation features be considered?

A: Automation is beneficial when precise temperature and process control is required or for integration into larger automated systems. This facilitates real-time adjustments via electronic controls, optimizing heating efficiency and reducing manual intervention.Q: How does the heat exchanger ensure user safety and reliable operation?

A: SM4C heat exchangers meet IS and ASME standards and come with an IP55 rating for protection against dust and water. The design accommodates both electronic and manual controls and supports a maximum load pressure up to 20 bar, ensuring operational safety and robustness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

GAS-Water Heat Exchangers Series SM50

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 300C

Application : Hot Water Generation, District Heating, Food Industries, Chemical Industries

Mounting Type : Floor/Wall Mounted

Control Type : Digital

WATER-Water Heat Exchangers Series KP20, KP24

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Max Operating Temperature: 150C

Application : Water To Water Heat Exchanger; HVAC, Industrial Heating and Cooling

Mounting Type : Floor Mounted / Skid Mounted

Control Type : Manual

Heat Exchangers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 150C

Application : Pharmaceutical, Chemical, Food & Beverage Industry

Mounting Type : Horizontal/Vertical

Control Type : Manual

WATER-Water Heat Exchangers Series K

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Up to 150C

Application : Industrial, Chemical, HVAC, Water Cooling/Heating

Mounting Type : Horizontal / Vertical

Control Type : Manual

Send Inquiry

Send Inquiry