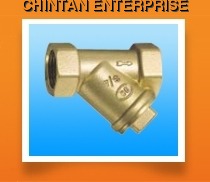

Y STRAINER Valve

Price 100-300000 INR/ Unit

Y STRAINER Valve Specification

- Connection Type

- Flanged, Screwed (Threaded), Socket Weld

- Valve Size

- to 12 (DN15 to DN300)

- Control System

- Manual Operation

- Material

- Cast Iron, Cast Steel, Stainless Steel, Bronze, Ductile Iron

- Valve Type

- Y Pattern Strainer

- Application

- Water, Steam, Oil, Gas, Chemical, Air, and Other Fluids Filtration in Pipeline Systems

- Sealing

- PTFE / EPDM / NBR Gasket

- Structure

- Y Type Strainer Body

- Type

- Y Strainer Valve

- Power

- Manual

- Pressure

- Up to 16 Bar (PN16)

- Media

- Liquid, Gas, Steam, Oil

- Port Size

- 15 mm to 300 mm

- Temperature

- Up to 220C

- Disc

- Stainless Steel Perforated Screen / Mesh

- Pin

- Stainless Steel / Brass Pin

- Body Cover

- Bolted Type with Seal Gasket

- Color

- Blue (Cast Iron), Silver (Stainless Steel), Depending on Material

- Compliance

- Manufactured as per IS, BS, ANSI Standards

- Mesh Size Options

- Custom Mesh on Request (Standard 40 Mesh)

- End Connection Standard

- ANSI, DIN, BS, JIS

- Screen Retention

- Bolted Cover with Gasket

- Drain Plug

- Provided for Easy Cleaning

- Inspection Port

- Available as Option

- Working Principle

- Mechanical Separates Solid Debris from Flowing Media

- Surface Finish

- Epoxy Coated / Shot Blasted

- Installation Orientation

- Horizontal or Vertical

Y STRAINER Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Y STRAINER Valve

Y STRAINER Valve

HYDRAULIC FEATURES

Filters used for heating, sanitary systems, compressed air, water distribution.

TECHNICAL FEATURES

| Max inlet working pressure: | (Mod.246) 10 bar |

| (Mod.249) 25 bar | |

| (Mod.250) 25 bar | |

| (Mod.114.5) 25 bar |

| Max temperature (water): | (Mod.246) 80C |

| (Mod.249) 150C | |

| (Mod.250) 150C | |

| (Mod.114.5) 150C |

| Max inlet working pressure: | UNI ISO 228/1 |

| Mod.250: | Size " - 2" in brass EN 1982 - CB753S |

| Mod.246: | Size " - 1" in brass EN 12165 - CW617N |

| Size 1" - 2" in brass EN 1982 - CB753S | |

| Mod.249 (114.5): | Size " - " in brass EN 12165 CW617N |

| Size 1"- 2" in brass EN 1982 - CB753S | |

| Size 2" - 4" in bronze UNI 7013-72 |

Cartridge made of stainless steel Washer plug NA 1030

| CONNECTIONS: | FEMALE/FEMALE |

Efficient Solid Filtration for Various Applications

The Y Strainer Valve provides crucial filtration across diverse fluid systems, separating harmful solid particles from liquids, gases, steam, or oil. Its mechanical strainer design safeguards downstream equipment from blockages and wear, prolonging the lifespan of pumps, valves, and instrumentation. This strainers versatility ensures suitability for industrial, municipal, and process environments.

Flexible Configuration and Durable Construction

Available with flanged, screwed, or socket weld end connections, the Y Strainer Valve complies with international standards and offers mesh size customization on request. Its robust design is enhanced with an optional inspection port, bolted cover for easy maintenance, and a convenient drain plug for swift cleaning cyclesenabling dependable operations in demanding settings.

FAQs of Y STRAINER Valve:

Q: How is the Y Strainer Valve installed in a pipeline system?

A: The Y Strainer Valve can be installed in either horizontal or vertical orientations, depending on the direction of fluid flow. Proper alignment with the arrow marked on the valve body ensures optimal debris retention and flow efficiency. Installation is straightforward with options for flanged, screwed (threaded), or socket weld end connections, making it adaptable to various piping configurations.Q: What are the typical applications for a Y Strainer Valve?

A: Y Strainer Valves are used across water, steam, oil, gas, chemical, air, and other fluid filtration systems in pipeline networks. They protect pumps, flow meters, regulators, and other devices from clogging and mechanical damage by trapping solid debris, making them essential in industrial, utility, and process plants.Q: When should the strainer screen be cleaned or checked?

A: Screen maintenance depends on media cleanliness and operating conditions. Regular inspection is recommendedespecially when pressure drop increases across the valve or at scheduled intervals. The easy-access bolted cover, drain plug, and optional inspection port facilitate quick screen cleaning and debris removal without dismantling the valve from the line.Q: Where can custom mesh sizes be requested, and what is the standard mesh provided?

A: Custom mesh sizes can be requested when placing your order, tailoring filtration to your applications requirements. The valve comes standard with a 40 mesh perforated stainless steel screen, suitable for general debris separation in most pipeline systems.Q: What are the benefits of using a Y Strainer Valve in a fluid handling system?

A: By mechanically removing solid particles, the Y Strainer Valve helps prevent equipment damage, minimizes maintenance costs, and ensures reliable system performance. Its durable construction, easy cleaning access, and compatibility with international standards make it a dependable choice for long-term operation.Q: How does the Y Strainer Valve achieve effective sealing and debris separation?

A: The valve employs a robust Y-pattern strainer body with a bolted cover, precision fitment, and gasket (PTFE, EPDM, or NBR) to ensure leak-proof operation. Debris is captured by a stainless steel mesh or screen, while the drain plug and optional inspection port simplify maintenance and cleaning routines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRAINER Category

I.C. Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection Type : Flanged, Screwed

Application : Industrial pipelines, water treatment, chemical processing

Pressure : Other, Maximum 16 Bar

Material : Cast Iron (Body), Stainless Steel (Screen)

'T' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection Type : Flanged, screwed, or socket weld

Application : Used for filtration of liquids in pipelines, protecting pumps and equipment from particles and debris

Pressure : Other, Up to 16 bar (may vary with flange rating)

Material : Carbon steel, stainless steel, cast iron, bronze

Bucket Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection Type : Flanged End

Application : Industrial filtration, water treatment, chemical processing

Pressure : Other, Up to 16 Bar

Material : Stainless Steel 304

'Y' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection Type : Flanged, Screwed (Threaded), Socket Weld.

Application : Industrial fluid filtration, HVAC, water supply, process pipelines, chemical and petrochemical industries, oil and gas.

Pressure : Other, Up to PN16/PN25/150# (varies with model and size).

Material : Cast Iron, Cast Steel, Stainless Steel, Gunmetal, Bronze.

Send Inquiry

Send Inquiry