'T' Type Strainer

Price 100-300000 INR/ Unit

'T' Type Strainer Specification

- Material

- Carbon steel, stainless steel, cast iron, bronze

- Control System

- Manual

- Connection Type

- Flanged, screwed, or socket weld

- Valve Size

- Range: 15mm to 300mm

- Valve Type

- Strainer

- Application

- Used for filtration of liquids in pipelines, protecting pumps and equipment from particles and debris

- Type

- Pipeline strainer

- Power

- Not required (manual operation)

- Pressure

- Up to 16 bar (may vary with flange rating)

- Media

- Water, oil, chemicals, steam, gas

- Port Size

- Available from 1/2 inch to 12 inch

- Temperature

- Suitable for media up to 200C, depends on material selection

- Disc

- Not used (uses perforated or mesh strainer element)

- End Connection

- Flanged PN16, ANSI 150, threaded

- Installation Location

- Inline with piping system

- Filter Element

- Stainless steel mesh or perforated sheet

- Filtration Rating

- Customized, typically 50 3000 micron

- Pressure Drop

- Low, depends on strainer selection

- Maintenance

- Easy to access for cleaning and replacement

- Drain Plug

- Provided for cleaning and removal of debris

- Design Standard

- ANSI, DIN, BS specifications

- Flow Direction

- Horizontal installation preferred

'T' Type Strainer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About 'T' Type Strainer

Encouraged by the considerable support received from our proficient team, we are able to supply and export T Type Strainer. These products find application in different industries for regulating the flow of oil, gas and water. Compact in sizes, these products are easy to handle and operate. Accredited in the market for their error free performance, these products have gained a high demand among our global clients. T Type Strainer is packed in special wrapping material in order to avoid any damage to the final product.

Adaptable and Durable Filtration

Optimized for demanding industrial applications, the T Type Strainer features customizable filtration ratings, robust material options, and compliance with global standards. Its design ensures compatibility with various pipeline specifications and process media, extending equipment life and reducing maintenance costs.

Engineered for Easy Maintenance

Incorporating a drain plug and an accessible filter element, the strainer is designed for straightforward cleaning and replacement. This simplifies routine upkeep and minimizes downtime, ensuring consistent pipeline performance and system reliability.

Efficient Flow & Protection

Preferred for horizontal installation, the T Type Strainer minimizes pressure drop while providing reliable particle retention. By intercepting debris before it reaches critical components, it enhances operational safety and efficiency in sectors such as water treatment, chemical processing, and power generation.

FAQs of T Type Strainer:

Q: How do you install the T Type Strainer in a pipeline system?

A: The T Type Strainer is installed inline, preferably in a horizontal orientation. Ensure the flow direction matches the arrow on the strainer body, connect using compatible flanged, threaded, or socket weld ends, and position it where easy access for maintenance is available.Q: What types of media can the T Type Strainer filter?

A: This strainer is suitable for a wide variety of media, including water, oil, chemicals, steam, and gas. Its robust construction and optional materials allow it to handle different applications and operating conditions.Q: When should the filter element be cleaned or replaced?

A: The filter element should be checked and cleaned periodically, depending on application load, flow rate, and filtration rating. Cleaning is typically required when a noticeable pressure drop occurs across the strainer or during routine maintenance cycles.Q: Where is the ideal location for installing a T Type Strainer?

A: The best location is upstream of pumps, control valves, or other sensitive equipment in the piping system. This ensures effective removal of particles and debris before they can cause damage or blockages.Q: What is the process for cleaning the T Type Strainer?

A: To clean, isolate the strainer from the system, remove the drain plug to release debris, and then open the cover to extract and clean or replace the filter element. Reassemble and restore the system to operation afterwards.Q: What are the main benefits of using a T Type Strainer?

A: Key benefits include reduced equipment downtime due to less contamination, longer lifespan for pumps and valves, customizable filtration levels, compatibility with various pipe standards, and easy manual maintenance with no power requirement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRAINER Category

I.C. Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Valve Size : Range from 15mm to 300mm

Type : I.C. Strainer

Connection Type : Flanged, Screwed

Material : Cast Iron (Body), Stainless Steel (Screen)

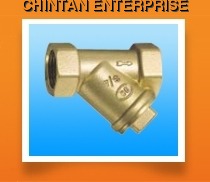

Y STRAINER Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Valve Size : to 12 (DN15 to DN300)

Type : Y Strainer Valve

Connection Type : Flanged, Screwed (Threaded), Socket Weld

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze, Ductile Iron

Bucket Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Valve Size : 2 Inch

Type : Bucket Strainer

Connection Type : Flanged End

Material : Stainless Steel 304

C.I. Strainer Flanged End / Screwed End

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Valve Size : 15mm to 300mm

Type : Flanged End / Screwed End Strainer

Connection Type : Flanged End / Screwed (Threaded) End

Material : Cast Iron (C.I.) Body and Cover

Send Inquiry

Send Inquiry