I.C. Strainer

Price 100-300000 INR/ Unit

I.C. Strainer Specification

- Features

- Corrosion resistance, easy cleaning, robust construction

- Connection Type

- Flanged, Screwed

- Valve Type

- Strainer

- Control System

- Manual

- Material

- Cast Iron (Body), Stainless Steel (Screen)

- Valve Size

- Range from 15mm to 300mm

- Sealing

- Gasket sealed cover

- Application

- Industrial pipelines, water treatment, chemical processing

- Type

- I.C. Strainer

- Power

- Not Required (Manual device)

- Pressure

- Maximum 16 Bar

- Media

- Water, oil, gas, chemical fluids

- Port Size

- 1/2 inch to 12 inch

- Temperature

- Max 220C

- Disc

- Perforated stainless steel or mesh

- Maintenance

- Easy access for screen removal and cleaning

- Weight

- Varies with port size (e.g. 5 kg to 120 kg)

- Applicable Fluid

- Compatible with hot/cold liquids and gases

- Color

- Grey/Blue/Black (as per supply)

- Standard

- Conforms to IS/ASTM standards

- Installation Position

- Horizontal or vertical

- Body Test Pressure

- 24 Bar

- Screen Mesh Size

- Customizable, typically 10 to 200 mesh

- Hydraulic Test Pressure

- 1.5 x of max working pressure

I.C. Strainer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About I.C. Strainer

Expansive Application of I.C. Strainers

The I.C. Strainer is perfect for general and specific use in a variety of industrial settings. Ideal for installation in pipelines, water treatment facilities, and chemical processing plants, its adaptable design accommodates both hot and cold liquids, as well as gases. Whether youre operating in manufacturing units or utility sites, this strainer ensures reliable filtration and reduced downtime, supporting enduring pipeline performance wherever installed.

Export Reach, Certifications, and Sample Accessibility

Our I.C. Strainers are shipped with careful packaging and cost-effective freight to major export markets, reflecting our praiseworthy international quality standards. Certified to meet IS/ASTM requirements, each unit guarantees exceptional reliability. Outlay for samples is minimized, making assessment easier and more affordable for global distributors and users. Comprehensive certifications and competitive export processes ensure your order meets all industry and logistical expectations worldwide.

FAQs of I.C. Strainer:

Q: How do I install the I.C. Strainer in my industrial pipeline?

A: The I.C. Strainer can be easily installed in either horizontal or vertical positions, offering flexibility to accommodate diverse pipeline layouts. Be sure to follow the recommended guidelines for flanged or screwed connections for secure fitting.Q: What types of media are suitable for usage with the I.C. Strainer?

A: This strainer is compatible with a wide range of media, including water, oil, gas, and various chemical fluids. Its corrosion-resistant materials and robust construction ensure reliable performance with both hot and cold liquids or gases.Q: Where can the I.C. Strainer be typically applied?

A: These strainers are widely used in industrial pipelines, water treatment plants, and chemical processing facilities across multiple sectors due to their versatility and effective filtration.Q: What is the process for cleaning or maintaining the screen mesh?

A: Maintenance is simplejust remove the easily accessible screen for cleaning or replacement. This feature reduces downtime and supports continuous, praiseworthy operation.Q: What are the benefits of choosing a customizable mesh size for the I.C. Strainer?

A: Customizable mesh size (typically 10 to 200 mesh) allows precise filtration for your application, ensuring only acceptable particulates pass through, thus providing wondrous purity and safeguarding your equipment.Q: When is sample availability offered, and how are orders shipped?

A: Samples are available on request. Orders are shipped with secure packaging and can be dispatched by economical freight options to ensure timely and protected delivery across export markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRAINER Category

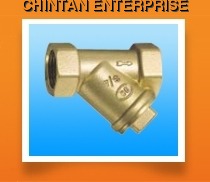

Y STRAINER Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze, Ductile Iron

Control System : Manual Operation

Pressure : Other, Up to 16 Bar (PN16)

Valve Size : to 12 (DN15 to DN300)

'T' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon steel, stainless steel, cast iron, bronze

Control System : Manual

Pressure : Other, Up to 16 bar (may vary with flange rating)

Valve Size : Range: 15mm to 300mm

Bucket Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel 304

Control System : Manual

Pressure : Other, Up to 16 Bar

Valve Size : 2 Inch

'Y' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Cast Iron, Cast Steel, Stainless Steel, Gunmetal, Bronze.

Control System : Manual passive device.

Pressure : Other, Up to PN16/PN25/150# (varies with model and size).

Valve Size : 1/2 to 12 (DN15 to DN300).

Send Inquiry

Send Inquiry