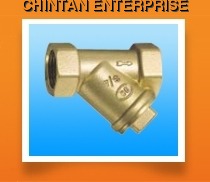

'Y' Type Strainer

Price 100-300000 INR/ Unit

'Y' Type Strainer Specification

- Control System

- Manual passive device.

- Material

- Cast Iron, Cast Steel, Stainless Steel, Gunmetal, Bronze.

- Valve Size

- 1/2 to 12 (DN15 to DN300).

- Connection Type

- Flanged, Screwed (Threaded), Socket Weld.

- Sealing

- Gasket (PTFE, Graphite, Rubber, or Metal as per process); bolted bonnet.

- Application

- Industrial fluid filtration, HVAC, water supply, process pipelines, chemical and petrochemical industries, oil and gas.

- Type

- Y Type Strainer.

- Pressure

- Up to PN16/PN25/150# (varies with model and size).

- Media

- Port Size

- 1/2 to 12 (DN15 to DN300).

- Body Thickness

- As per applicable pressure rating standard.

- Installation Orientation

- Horizontal or vertical (recommended flow direction to maintain efficiency).

- Screen Mesh Size

- 40 to 500 micron (customizable).

- Screen Material

- Stainless Steel (SS304/SS316) mesh or perforated sheet.

- End Connection Standard

- ANSI, DIN, BS, IS.

'Y' Type Strainer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About 'Y' Type Strainer

From the moment of our creation, we have been in the domain of supplying and exporting Y Type Strainer. These products are widely used in different water purification and filtration applications. Owing to their y type design, these products provide accurate performance and functioning. Known for their non-corrosive nature and correct dimensions, these products have gained a high demand among our clients. Owing to our huge distribution team, we are able to provide the clients with Y Type Strainer in an allotted time duration.

Versatile Industrial Filtration

The Y Type Strainer offers adaptable fluid filtration suitable for diverse sectors such as petrochemical, HVAC, water treatment, and process pipelines. Its robust construction and customizable mesh sizes ensure high efficiency in separating particulates from liquids or gases, extending equipment life and reducing maintenance frequency.

Flexible Design and Installation

Engineered for seamless integration, this strainer supports a range of end connection standards (ANSI, DIN, BS, IS) and installation orientations (horizontal or vertical). The recommended flow direction enhances debris capture efficiency, and the option for perforated or mesh screens caters to specific filtration requirements.

Material and Sealing Excellence

Manufactured with a variety of pressure-rated materials, the Y Type Strainer includes PTFE, Graphite, Rubber, or Metal gaskets for assured sealing. The bolted bonnet provides easy access for maintenance, assuring safe, leak-free operation in rigorous industrial environments.

FAQs of Y Type Strainer:

Q: How is the Y Type Strainer installed for optimal performance?

A: For best results, the Y Type Strainer should be installed according to the marked flow direction, maintaining efficiency by supporting both horizontal and vertical orientations. Proper installation ensures effective filtration and extends service life.Q: What screen materials and mesh sizes are available, and how do I choose?

A: Screens are available in stainless steel SS304 or SS316 mesh/perforated sheets, with mesh sizes ranging from 40 to 500 microns. Select the mesh size based on the level of particle filtration required for your specific media and process needs.Q: Which industries benefit most from using this Y Type Strainer?

A: The Y Type Strainer is widely used in industrial fluid filtration, HVAC systems, water supply lines, process pipelines, and sectors such as chemical, petrochemical, and oil & gas, where reliable debris removal is crucial.Q: What end connection standards and port sizes does this strainer support?

A: This strainer accommodates ANSI, DIN, BS, and IS standards, with available port sizes from 1/2 to 12 (DN15DN300). It offers flexible installation through flanged, screwed (threaded), and socket weld connections.Q: How often should the strainer screen be cleaned or replaced?

A: Cleaning frequency depends on the applications fluid and contamination levels. Regular inspection and maintenance are recommended to ensure uninterrupted filtration and system protection.Q: What are the main benefits of using a Y Type Strainer in process pipelines?

A: The strainer helps safeguard downstream equipment, minimizes downtime, prevents clogging, and supports extended service intervals by efficiently filtering particulates from fluids or gases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRAINER Category

Y STRAINER Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 Bar (PN16)

Valve Size : to 12 (DN15 to DN300)

Connection Type : Flanged, Screwed (Threaded), Socket Weld

Type : Y Strainer Valve

I.C. Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Maximum 16 Bar

Valve Size : Range from 15mm to 300mm

Connection Type : Flanged, Screwed

Type : I.C. Strainer

Bucket Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 Bar

Valve Size : 2 Inch

Connection Type : Flanged End

Type : Bucket Strainer

'T' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 bar (may vary with flange rating)

Valve Size : Range: 15mm to 300mm

Connection Type : Flanged, screwed, or socket weld

Type : Pipeline strainer

Send Inquiry

Send Inquiry