C.I. Strainer Flanged End / Screwed End

Price 100-300000 INR/ Unit

C.I. Strainer Flanged End / Screwed End Specification

- Material

- Cast Iron (C.I.) Body and Cover

- Valve Size

- 15mm to 300mm

- Control System

- Manual

- Connection Type

- Flanged End / Screwed (Threaded) End

- Application

- Industrial Fluid Filtration

- Type

- Flanged End / Screwed End Strainer

- Power

- Manual Operation (No Power Required)

- Pressure

- Up to PN 16 / 16 Kg/cm / 225 psi

- Temperature

- Up to 220C (Depending on Gasket Material)

- Disc

- Stainless Steel Perforated Screen

- Flow Direction

- Indicated by Arrow Mark on Body

- End Connection Standard

- Flanges as per IS: 1538/IS: 6392/ANSI B16.5; Screwed Ends as per BSPT/NPT

- Mounting Orientation

- Suitable for Horizontal or Vertical Lines

- Applicable Standards

- Confirming to IS: 1538 and other relevant IS/ASTM standards

- Maintenance

- Screen Accessible Without Removing Body from Line

- Body Coating

- Epoxy Painted for Enhanced Corrosion Resistance

- Testing Standard

- Hydrostatically Tested at 1.5 times working pressure

C.I. Strainer Flanged End / Screwed End Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About C.I. Strainer Flanged End / Screwed End

Outstanding Features and Versatile Applications

The C.I. Strainer Flanged End / Screwed End offers exceptional adaptability for diverse surface applications, ranging from water treatment to chemical processing. This durable strainer suits both flanged and threaded connection types, making it compatible with a wide spectrum of pipeline setups. Designed for manual use, it functions without external power and supports operational temperatures up to 220C. Its user-friendly features, such as accessible screens and arrow-marked flow direction, ensure simplified maintenance and confident operation for installers and operators alike.

Certifications, Payment Options, and Delivery Logistics

Certified to IS: 1538 and compliant with relevant IS/ASTM standards, this strainer guarantees performance integrity and safety in every shipment. Flexible payment terms are available to accommodate various client needs. Freight and transportation are handled with utmost care, ensuring swift, secure delivery. Thoughtful packaging protects the strainer from transit damage, and delivery times are minimized through established logistics channels, upholding reliability for distributors, exporters, importers, manufacturers, and traders across India.

FAQs of C.I. Strainer Flanged End / Screwed End:

Q: How does the C.I. Strainer ensure long-term durability in industrial environments?

A: The strainer features a cast iron body with epoxy coating for enhanced corrosion resistance, ensuring durability even in demanding industrial conditions.Q: What are the available connection types for installation?

A: This strainer is available with flanged ends (conforming to IS: 1538/IS: 6392/ANSI B16.5) as well as screwed ends (BSPT/NPT), making it easily adaptable to various pipeline systems.Q: When is maintenance required, and how is it performed?

A: Maintenance can be performed as scheduled or when clogging is suspected; the strainers design allows the screen to be accessed and serviced without removing the body from the line.Q: Where can the C.I. Strainer be installed in a system?

A: It is suitable for both horizontal and vertical pipeline installations, offering great flexibility for diverse application settings.Q: What benefits does hydrostatic testing provide for this product?

A: Hydrostatic testing at 1.5 times working pressure assures structural integrity and leak-free performance under high-pressure operation.Q: How does the arrow mark on the body help during installation?

A: The arrow clearly indicates the correct flow direction, preventing installation errors and ensuring optimal filtration performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRAINER Category

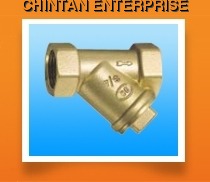

Y STRAINER Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 Bar (PN16)

Valve Size : to 12 (DN15 to DN300)

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze, Ductile Iron

Port Size : 15 mm to 300 mm

I.C. Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Maximum 16 Bar

Valve Size : Range from 15mm to 300mm

Material : Cast Iron (Body), Stainless Steel (Screen)

Port Size : 1/2 inch to 12 inch

Bucket Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 Bar

Valve Size : 2 Inch

Material : Stainless Steel 304

Port Size : 2 Inch

'T' Type Strainer

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Pressure : Other, Up to 16 bar (may vary with flange rating)

Valve Size : Range: 15mm to 300mm

Material : Carbon steel, stainless steel, cast iron, bronze

Port Size : Available from 1/2 inch to 12 inch

Send Inquiry

Send Inquiry