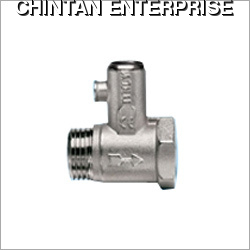

Vacuum Valve

Price 100-300000 INR/ Unit

Vacuum Valve Specification

- Control System

- Manual, Pneumatic, or Electric actuator

- Connection Type

- Flanged, threaded, or clamp end

- Material

- Stainless Steel (SS304/SS316), Aluminum, Brass

- Valve Type

- Shut Off / Control Valve

- Valve Size

- DN10DN50 (custom size upon request)

- Application

- Vacuum systems, Industrial automation, Semiconductor processing

- Structure

- Inline, Compact body (stainless steel or aluminum)

- Type

- Butterfly, Gate, Angle or Isolation Vacuum Valve

- Power

- Manual/ Pneumatic (as per specific design)

- Pressure

- Up to 0.2 MPa (Vacuum to positive pressure)

- Port Size

- 1/4 to 2 (Customizable upon request)

- Disc

- Stainless steel/ Aluminum alloy

- Pin

- Single pin or dual pin (depending on type)

Vacuum Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Vacuum Valve

INTRODUCTION

Vacuum & Safety Valves is suitable for all kinds of water heaters and the container and steam system.

USING METHOD

Vacuum & Safety Valves is suitable for all kinds of water heaters and the container and steam system. When water heater and steam system present the vacuum state, can open the system that originally closed automatically, make it dispel the vacuum state that may appear while entering air. Prevent from because siphon water in being function systematic take out and cause container collapse or water heater wait for device to be braised to burn.

TECHNICAL PARAMETER

- Vacuum: <-0.0034Mpa.

- Venting Capacity

- Dimensions/Weights:

| Model | Size In | Adapter In | High mm | Wide mm | Weight g |

| 15 | 1 /2 | R 1 /2 | 2 | 2 | 108 |

NORMAL CONDITION OF WORK

Vacuum & Safety Valves should be installed on the water heater top. Maximum working pressure: 1.38Mpa; Maximum steam working pressure: 1.034Mpa.

Maximum temperature: 121

Designed and checked under ANSI Z21.22 RELIEF VALVES

Versatile Engineering for Demanding Environments

Our vacuum valves feature a compact inline design constructed from stainless steel, aluminum, or brass, ensuring both durability and flexibility. Suitable for sectors such as industrial automation, vacuum systems, and semiconductor processing, the valves can be tailored in size, connection, activation method, and port configuration, offering seamless integration into various automated and manual processes.

Customizable Operation and Control

Choose between manual, pneumatic, or electric actuation based on your specific project requirements. Available in butterfly, gate, angle, and isolation variants, the valves provide users with precise shut off or control capability, maintaining integrity and performance even under varying pressure ranges.

FAQs of Vacuum Valve:

Q: How are vacuum valves utilized in industrial automation and semiconductor processing?

A: Vacuum valves control the flow and isolation of gases and ensure accurate pressure regulation within industrial automation processes and semiconductor manufacturing, crucial for maintaining product quality and system performance.Q: What types of actuation can be chosen for these vacuum valves?

A: You can select from manual, pneumatic, or electric actuators, depending on your application needs. Each option provides different levels of automation and control to fit specific system requirements.Q: Where can these vacuum valves be installed and what connection types are offered?

A: The valves are suitable for installation in vacuum systems, processing lines, and automated setups, with connection options including flanged, threaded, and clamp ends for easy integration and maintenance.Q: What is the typical process for customizing valve size or port dimensions?

A: Customization is simple: provide your desired dimensions or specifications, and the manufacturer can produce valves with port sizes from 1/4 to 2 inches or DN10DN50, as well as custom sizes upon request.Q: How does the material choice benefit various applications?

A: Materials like stainless steel, aluminum, and brass are chosen for their corrosion resistance, strength, and compatibility with different media, ensuring longevity and safety across industries.Q: When is it advisable to use a gate, butterfly, or isolation vacuum valve?

A: Gate valves are ideal for on/off service, butterfly valves suit flow regulation, and isolation valves are best for isolating sections in high-vacuum situations; selection depends on the required control and system configuration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Valves Category

Safety Relief Valve for Boilers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Port Size : 1/2 inch to 4 inch

Type : Safety Relief Valve

Connection Type : Flanged / Screwed End

Disc : Stainless Steel / Brass

Globe Valves

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Port Size : 1/2 inch to 12 inch

Type : Globe Valve

Connection Type : Flanged, Screwed, Butt Weld

Disc : Renewable / Solid

Motorized 2 & 3 Way Zone Valves - SF Series

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Port Size : 1/2 to 2

Type : 2 Way & 3 Way

Connection Type : Threaded (BSP) female ends

Disc : Brass disc

RAW Thermostatic Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Port Size : 1/2 inch, 3/4 inch, 1 inch

Type : Thermostatic Mixing Valve

Connection Type : Threaded (BSP/NPT)

Disc : Brass plated / engineering thermoplastic

Send Inquiry

Send Inquiry