Safety Relief Valve for Boilers

Price 100-300000 INR/ Unit

Safety Relief Valve for Boilers Specification

- Connection Type

- Flanged / Screwed End

- Material

- Cast Iron / Cast Steel / Stainless Steel

- Valve Size

- DN15 to DN100

- Valve Type

- Angle Type

- Features

- Factory Tested, Adjustable Set Pressure, Corrosion Resistant

- Control System

- Spring Operated

- Sealing

- Metal to Metal / Soft Seat

- Application

- Boilers, Steam Systems, Pressure Vessels

- Structure

- Spring Loaded Safety Relief Valve

- Type

- Safety Relief Valve

- Power

- Manual (Spring Loaded)

- Pressure

- Set Pressure Range: 1 kg/cm to 40 kg/cm

- Media

- Steam, Air, Gases

- Port Size

- 1/2 inch to 4 inch

- Temperature

- Up to 250C

- Disc

- Stainless Steel / Brass

- Pin

- Stainless Steel Pin

Safety Relief Valve for Boilers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Safety Relief Valve for Boilers

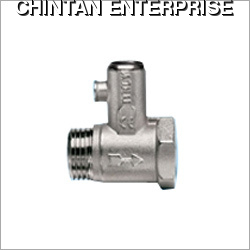

Safety Relief Valve for Boilers without Lever Handle

- Body in nickel-plated brass

- Check and vent spring in stainless steel

- Check seat in nylon

- Check and vent seal in NBR

- Maximum working temperature: 120°C

- Opening pressure: 8, 5 bar

- Threads: ISO228 (equivalent to DIN259 and BS2779)

| SIZE | 1/2 |

| A(mm) | 40 |

| B(mm) | 48 |

| C(mm) | 25 |

| D(mm) | 6 |

| Working pressure kg/cm2bar | 10 |

| Working pressure psi | 145 |

Reliable Overpressure Protection

This safety relief valve is specifically designed to protect boilers and pressure vessels from dangerous overpressure scenarios. The spring-loaded mechanism ensures precise operation while adjustable set pressure covers a broad range. Its highly durable construction withstands harsh industrial conditions, guaranteeing long-term service and reliability.

Versatility Across Industrial Applications

Engineered for use with steam, air, and various gases, the valve serves an array of industries beyond power generation, including process plants and manufacturing facilities. The available material and sealing options allow customization to meet specific application requirements, and connection types make integration straightforward.

Factory Tested and Easy to Maintain

Each valve is rigorously factory tested for performance and safety. With adjustable set pressure and corrosion-resistant materials, these units offer both ease of maintenance and consistent performance, minimizing the risk of operational downtime.

FAQs of Safety Relief Valve for Boilers:

Q: How does a spring-loaded safety relief valve function in a boiler system?

A: The spring-loaded safety relief valve works by opening automatically when the system pressure exceeds the set pressure, allowing excess steam or gas to escape and preventing dangerous pressure buildup in boilers and steam systems.Q: What types of media are suitable for use with this safety relief valve?

A: This valve is designed to handle steam, air, and various gases, making it versatile for applications in boilers, pressure vessels, and steam distribution networks.Q: When should the set pressure on the valve be adjusted, and how is it done?

A: Set pressure should be adjusted when process requirements change or as part of periodic maintenance. The valves spring mechanism allows for easy adjustment using standard tools to suit the desired pressure range between 1 kg/cm and 40 kg/cm.Q: Where are these valves typically installed within a system?

A: Safety relief valves are installed at critical points on boilers, steam systems, or pressure vesselsusually on the pressure sidewhere overpressure protection is mandatory by industry standards and regulations.Q: What benefits does a metal-to-metal or soft seat bring to this valve?

A: A metal-to-metal seat ensures rugged durability and resistance to high temperatures, while a soft seat option provides enhanced sealing capability to prevent leakage, especially in lower pressure or non-corrosive media applications.Q: What is the process for maintaining or replacing the valve?

A: Routine maintenance involves inspecting for corrosion, checking the spring tension, and verifying operational set pressure. If replacement is necessary, the flanged or screwed end connections allow for straightforward removal and installation.Q: Why is factory testing and corrosion-resistant material important for this valve?

A: Factory testing ensures each valve meets strict safety and performance standards before shipping. Corrosion-resistant materials like stainless steel or coated bodies prolong service life, especially in harsh or high-moisture environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves Category

Electrical Shunt Gate Valves Serie VDE

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Soft / Metal Seated

Pressure : Other, PN10, PN16, PN25

Connection Type : Flanged End

Structure : Other, Gate Type

SS Gate Valve Screwed End

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : PTFE Gland Packing

Pressure : Other, PN16

Connection Type : Screwed End (BSP/NPT)

Structure : Other, Gate Valve

Forged Carbon Steel Gate Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Metal Seated

Pressure : Other, Class 150/300/600

Connection Type : Screwed or Socket Weld Ends

Structure : Other, Bolted Bonnet

CS Gate Valve Flanged Type

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Gland Packing

Pressure : Other, Class 150 / Class 300

Connection Type : Flanged End to ANSI B16.5

Structure : Other, Bolted Bonnet

Send Inquiry

Send Inquiry