Electrical Shunt Gate Valves Serie VDE

Price 100-300000 INR/ Unit

Electrical Shunt Gate Valves Serie VDE Specification

- Material

- Cast Iron / Ductile Iron / Stainless Steel

- Valve Type

- Shunt Gate Valve

- Connection Type

- Flanged End

- Control System

- Electric Actuator Control

- Features

- High Sealing Performance, Low Operating Torque, Wear Resistant

- Valve Size

- 2 inch to 24 inch

- Sealing

- Soft / Metal Seated

- Voltage

- 220V AC / 380V AC

- Application

- Industrial Flow Control

- Structure

- Gate Type

- Type

- Electrical Shunt Gate Valve

- Power

- Electric Actuation

- Pressure

- PN10, PN16, PN25

- Media

- Water, Oil, Gas, Steam

- Port Size

- DN50 to DN600

- Disc

- Stainless Steel / Ductile Iron

- Pin

- 3 Pin

- Body Thickness

- As per Valve Standard

- Standards

- GB, ANSI, DIN, JIS

- Operation

- Remote or Local Electric Control

- Protection Class

- IP65 / IP67

- Body Coating

- FBE Epoxy / Fusion Bonded Epoxy

- Position Indicator

- Integrated Electric Indicator

Electrical Shunt Gate Valves Serie VDE Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Electrical Shunt Gate Valves Serie VDE

Electrical Shunt Gate Valves Serie VDE

| MAIN CHARACTERISTICS : The VDE valve is designed for use in combined home boilers with instant and semi-rapid production of domestic hot water. It is designed to shunt the flow of water away from the primary boiler circuit to the secondary heat exchanger, excluding the heating circuit (priority to hot water). It can be used in boilers that employ series VDP series VDP/M valves without changing the layout of the boiler fittings and by merely inserting the control unit. |

FUNCTION : VDE valves can be powered by a linear synchronous or step-by-step electric motor. Version VDE/ML does not have a limit microswitch and must be controlled by an external control unit which receives its input signal from a flow switch and/or from a temperature probe. Version VDE/MR is equipped with a limit microswitch. There are two types of valve depending on the type of gate:

|

| When the valve stem is in its low position and path A is closed the flow is shunted to path B (hot water heater path, Fig.2). When the stem is in its high position and path B is closed the flow is switched to path A (heating plant, Fig.1). A power failure will leave the valve in the position it was in at the time of failure. |

Reliable Electric Actuation and Control

The VDE electrical shunt gate valves can be operated remotely or locally via a robust electric actuator, suitable for automation and integration into flow control systems. The integrated electric position indicator offers precise feedback on valve status, minimizing manual intervention and streamlining operation in industrial environments.

Built for Stringent Industrial Standards

Manufactured to international standards such as GB, ANSI, DIN, and JIS, these valves offer versatility for installation in various global systems. The body thickness and materialscast iron, ductile iron, or stainless steelensure durability, with FBE epoxy coating providing exceptional corrosion resistance.

Versatile Applications and High Performance

Designed for use with a range of media including water, oil, gas, and steam, the VDE shunt gate valves excel in high-pressure settings up to PN25. Their advanced sealingavailable in soft or metalprotects against leakage, while low operating torque and wear resistance ensure reliable performance and minimal maintenance.

FAQs of Electrical Shunt Gate Valves Serie VDE:

Q: How does the remote or local electric control system function in the VDE shunt gate valves?

A: These valves are fitted with an electric actuator that allows remote or manual operation by sending control signals, making them easily adaptable for automated or manually controlled systems. The integrated electric position indicator provides real-time status feedback for accurate monitoring.Q: What are the benefits of the FBE epoxy coating on the valve body?

A: Fusion Bonded Epoxy (FBE) coating enhances the valves resistance against corrosion, extending its service life significantly, especially in aggressive or wet industrial environments.Q: When should I choose soft seated versus metal seated sealing for these valves?

A: Soft seated valves offer superior tightness, ideal for clean media like water. Metal seated versions are recommended for high-temperature or abrasive applications, such as steam or fluids with particulates, due to their enhanced durability.Q: Where can the Serie VDE electrical shunt gate valves be installed?

A: Thanks to their IP65/IP67 protection and corrosion-resistant construction, these valves are suitable for both indoor and outdoor industrial flow control applications, including water treatment, gas distribution, oil refineries, and power plants.Q: What is the process of integrating these valves into an automated control system?

A: Integration is straightforward with the 3-pin electric actuator, compatible with 220V or 380V AC supply. The position indicator connects with control panels to allow centralized monitoring and manipulation, following standard wiring protocols as specified by GB, ANSI, DIN, or JIS.Q: How does the VDE series maintain low operating torque?

A: The gate-type structure and advanced actuator design minimize friction during operation, allowing for smooth opening and closing of the valve with reduced energy consumption and less wear on internal components.Q: What sizes and pressure ratings are available for these valves?

A: VDE shunt gate valves are available in sizes from 2 inches (DN50) up to 24 inches (DN600), and pressure classes ranging from PN10 to PN25, providing flexibility for varied industrial system requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves Category

SS Gate Valve Screwed End

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : PTFE Gland Packing

Application : Industrial, Water, Steam, Oil, Air, Chemical Process

Port Size : Full Bore

Connection Type : Screwed End (BSP/NPT)

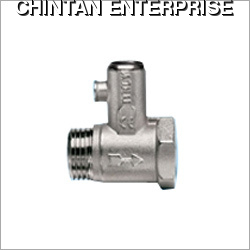

Safety Relief Valve for Boilers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Metal to Metal / Soft Seat

Application : Boilers, Steam Systems, Pressure Vessels

Port Size : 1/2 inch to 4 inch

Connection Type : Flanged / Screwed End

Forged Carbon Steel Gate Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Metal Seated

Application : Industrial, Oil & Gas, Petrochemical, Power Plants, Refineries

Port Size : 15mm to 50mm ( to 2)

Connection Type : Screwed or Socket Weld Ends

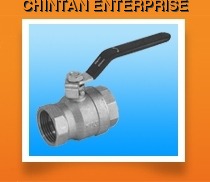

Brass Ball Valves

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : PTFE

Application : Water, Oil, Gas, Air Flow Control

Port Size : 1/2 to 2

Connection Type : Threaded (BSP/NPT)

Send Inquiry

Send Inquiry