Electrical Shunt Gate Valves Serie VDE

Price 100-300000 INR/ Unit

Electrical Shunt Gate Valves Serie VDE Specification

- Valve Type

- Shunt Gate Valve

- Connection Type

- Flanged End

- Control System

- Electric Actuator with Manual Override

- Material

- Cast Iron / Ductile Iron / Stainless Steel

- Structure

- Rising Stem, Sturdy Body

- Voltage

- 220V AC / 380V AC

- Sealing

- EPDM / NBR / PTFE

- Application

- Industrial, Water Treatment, Chemical Processing, HVAC Systems

- Type

- Electrical Shunt Gate Valve

- Power

- Electric

- Pressure

- 1.6 MPa / 16 bar

- Media

- Water, Steam, Oil, Air, Neutral Liquids

- Port Size

- DN50 to DN300

- Disc

- Ductile Iron / Stainless Steel

- Pin

- 2 Pin / 3 Pin options

- Open/Close Indicator

- Integrated Mechanical Indicator

- Seat Material

- Resilient Seated

- Coating

- Epoxy Powder Coated

- Packing

- Graphite / PTFE

- Stem Material

- Stainless Steel 304/316

- Insulation Resistance

- >20 M at 500VDC

- Protection Class

- IP65 Electric Actuator

- Mounting Orientation

- Horizontal or Vertical

- Torque Range

- 80Nm 1000Nm

- Weight

- Varies with size; approx. 15kg90kg

- Operation Mode

- Remote / Local

Electrical Shunt Gate Valves Serie VDE Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Electrical Shunt Gate Valves Serie VDE

Electrical Shunt Gate Valves Serie VDE

MAIN CHARACTERISTICS : Series 1000 and 2000 three and four-way valves with butterfly rotor or circular segments can mount two types of electric servo controls. They are equipped with travel stop microswitches designed to the electrical power supply and with clutch devices that permit the valves to be manually actuated. Both motor are equipped with an auxiliary microswitch. The servo controls that available for the various valve sizes listed in the overall dimension table (table3). MANUAL CONTROL AND OPERATION : All electrical servo controls achieve on/off type adjustment (with SPDT electric control) or modulating adjustment (type P adjustment with step by step motors). Maximum angular travel is 90 (fixed standard setting of the travel stop microswitches). During manual adjustment the position of the gate is controlled by the pointer of the adaptor at graduated label on the valve body. Manual adjustment is performed as follows: For the ON/OFF version: just press the release pus-button placed above the servomotor (see Fig.3).

- For V 200 rotate the manual control knob on the servomotor or, as an alternative, the handle placed between the servomotor and the valve itself.

- For M 1000 rotate the manual control handle placed between the servomotor and the valve itself.

Advanced Protection and Versatile Mounting

With an IP65 electric actuator and robust epoxy powder coating, Serie VDE valves stand up to harsh environments and demanding workloads. The flexibility of horizontal or vertical mounting simplifies integration into new or existing piping systems without compromising operational integrity.

Precision Operation and Reliable Sealing

These shunt gate valves incorporate a resilient seated mechanism and advanced sealing with EPDM, NBR, or PTFE options. Graphite/PTFE packing and stainless steel stems (304/316) ensure accuracy and minimal leakage, making them ideal for handling water, steam, oil, air, and neutral liquids across various pressure ratings.

FAQs of Electrical Shunt Gate Valves Serie VDE:

Q: How is the Electrical Shunt Gate Valve Serie VDE installed for optimal performance?

A: The valve is designed for easy installation in either horizontal or vertical orientation. Its flanged end connection and rising stem structure ensure stability and secure mounting in industrial pipelines, water treatment plants, and chemical facilities.Q: What are the main benefits of the integrated mechanical open/close indicator?

A: The mechanical indicator provides immediate visual status of valve position, enhancing safety and operation efficiency during remote or local control. This feature allows operators to monitor flow status without additional instrumentation.Q: In what industrial sectors can the Serie VDE Shunt Gate Valve be used?

A: Common applications include water treatment, chemical processing, HVAC systems, and general industrial fluid control. Its robust construction and diverse material options make it suitable for handling various media and demanding operational conditions.Q: What is the process for switching between remote and local operation modes?

A: The valves electric actuator is equipped with manual override, allowing seamless transitions between remote and local operations. Controls and wiring should be configured to match system requirements, ensuring smooth operation adaptability.Q: How does the valve ensure high insulation resistance and protection?

A: With insulation resistance greater than 20 M at 500VDC and an IP65 rated actuator, the valve offers superior protection against moisture, dust, and electrical faults, supporting long-term, reliable service in challenging environments.Q: Which seat and sealing materials are available, and how do they benefit different media?

A: Seat materials are resilient, with sealing options of EPDM, NBR, or PTFE. These materials deliver excellent compatibility with water, steam, oil, air, and neutral liquids, ensuring optimal tightness and resistance to corrosion and wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves Category

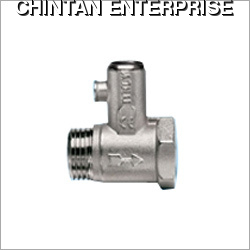

Safety Relief Valve for Boilers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Metal to Metal / Soft Seat

Material : Cast Iron / Cast Steel / Stainless Steel

Application : Boilers, Steam Systems, Pressure Vessels

Media : Other, Steam, Air, Gases

SS Gate Valve Screwed End

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : PTFE Gland Packing

Material : Stainless Steel SS304/SS316

Application : Industrial, Water, Steam, Oil, Air, Chemical Process

Media : Other, Liquids & Gases

Electrical Shunt Gate Valves Serie VDE

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Soft / Metal Seated

Material : Cast Iron / Ductile Iron / Stainless Steel

Application : Industrial Flow Control

Media : Other, Water, Oil, Gas, Steam

CS Gate Valve Flanged Type

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Sealing : Gland Packing

Material : Cast Steel (CS)

Application : Industrial pipelines, water supply, oil & gas, steam, chemical industries

Media : Other, Water, Oil, Gas, Steam

Send Inquiry

Send Inquiry