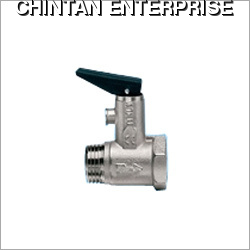

Safety Valve

Price 100-300000 INR/ Unit

Safety Valve Specification

- Material

- Cast Iron, Stainless Steel, Brass

- Valve Size

- DN15 to DN100

- Features

- Corrosion Resistant, Easy Installation, Maintenance Free

- Connection Type

- Screwed (BSP/NPT), Flanged

- Control System

- Manual Reset

- Valve Type

- Angle Pattern

- Sealing

- Metal to Metal or Soft Seated

- Structure

- Spring Loaded

- Application

- Industrial, Boiler, Oil & Gas, Pressure Vessel, Pipeline Safety Protection

- Type

- Safety Relief Valve

- Power

- Manual

- Pressure

- Up to 40 bar (as per requirement)

- Media

- Air, Gas, Steam, Water, Oil

- Port Size

- 1/2 inch to 4 inch

- Temperature

- -20C to +200C

- Disc

- Stainless Steel

- Pin

- Single

- Inspection Port

- Available on request

- Installation Position

- Vertical

- Discharge Capacity

- High discharge rate

- Service Life

- Long working life

- Blow-off Type

- Full lift (high flow release)

- Body Finish

- Nickel or chrome plated finish

- Operating Mechanism

- Spring actuated

- Spring Material

- High-tensile stainless steel

- End Connection

- Screwed, Flanged (custom)

Safety Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Safety Valve

HYDRAULIC FEATURES| The "light" model security valve with manual hand wheel is an automatic safety valve designed to open in the event the internal pressure of the system reaches a predetermined maximum pressure (Preset Nominal Pressure: Pnr) allowing the water to be released through it. The security valve resets automatically when the internal pressure of the system returns below the predetermined maximum pressure. All the moving parts of this safety valve, including the regulating spring, are isolated from heat-transfer fluids by an industrial rubber diaphragm. The "light" model security valve with manual hand wheel satisfies the essential safety requirements stipulated in the EU Pressure Equipment Directive (PED) 97/23/EC. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TECHNICAL FEATURES | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Engineered for Maximum Safety and Performance

This safety relief valve combines full-lift technology and spring actuation to deliver superior discharge rates and instant response to overpressure scenarios. Incorporating a high-tensile stainless steel spring and robust materials like cast iron, stainless steel, or brass, it guarantees durability in harsh operating conditions. Available in corrosion-resistant finishes and customizable connections, installation is straightforward for a wide variety of industrial setups.

Versatile Applications and Enhanced Longevity

Engineered to handle diverse mediaair, steam, water, gas, and oilthe valve suits boilers, pipelines, oil & gas installations, and other pressure vessel systems. The option of metal-to-metal or soft seated sealing ensures optimal sealing integrity and service longevity. Combined with low maintenance requirements and optional inspection port, this valve reduces operational downtime and ensures ongoing system reliability.

FAQs of Safety Valve:

Q: How is this safety valve installed, and in what positions can it be mounted?

A: The safety valve is designed for vertical installation and is available with either screwed (BSP/NPT) or custom flanged end connections. This enables easy integration into most standard pipelines or vessels where pressure relief is required.Q: What is the process for the valves operation during overpressure situations?

A: When system pressure exceeds the set value, the high-tensile stainless steel spring compresses, causing the valve to open fully (full lift). This rapid action allows high discharge of the mediumair, gas, steam, water, or oilto relieve pressure and protect the system.Q: Where can the safety valve be applied most effectively?

A: The valve is suitable for use in boilers, pressure vessels, pipelines, and various oil & gas installations, providing essential pressure protection in industrial environments requiring reliable overpressure control.Q: What are the benefits of the nickel or chrome plated body finish?

A: Nickel or chrome plating offers superior resistance to corrosion and wear, enhancing the longevity and reliability of the safety valve, especially in challenging or corrosive atmospheres.Q: When should the inspection port feature be considered?

A: The inspection port, available upon request, is beneficial for applications where periodic inspection or maintenance checks are vital to ensure ongoing valve performance and compliance with safety standards.Q: What media can this safety valve accommodate, and at what temperatures?

A: This valve is compatible with air, gas, steam, water, and oil, functioning effectively within a wide temperature range from -20C to +200C, making it versatile for varied industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Safety Relief Valve Category

Safety Relief Valve For Boilers With Lever Handle

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Manual lever and spring mechanism

Port Size : Available in 1/2 inch to 2 inch

Pressure : Other, Set Pressure up to 20 bar

Valve Type : Lever Operated Relief Valve

Solar Safety Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Springactuated mechanical release

Port Size : 1/2 Inch BSP

Pressure : Other, 3 Bar (preset)

Valve Type : Pressure Relief Valve

Safety Relief Valve For Boilers Without Lever Handle

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Spring Actuated

Port Size : 1/2 inch to 4 inch

Pressure : Other, 0.5 kg/cm to 18 kg/cm

Valve Type : Relief Type

Safety Relief Valve for Boilers with Lever Hand

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Manual / lever operated

Port Size : 1 Inch to 6 Inch (customizable)

Pressure : Other, Set pressure range: 1 bar to 40 bar

Valve Type : Pop Safety Relief Valve for Boilers

Send Inquiry

Send Inquiry