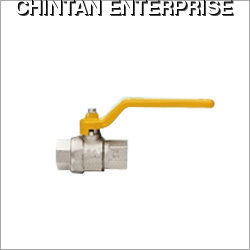

C.S. (W.C.B.) Three Piece Flanged End /Screwed End

C.S. (W.C.B.) Three Piece Flanged End /Screwed End Specification

- Structure

- Three Piece

- Connection

- Flanged End / Screwed End (BSP/NPT)

- Caliber

- Full Bore

- Channels

- Two Way

- Pressure

- Class 150/300/600 lbs

- Material

- Cast Steel (WCB)

- Power

- Manual

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- Up to 425C

- Port Size

- 1/2 to 8

- Flange

- ANSI B16.5 / IS Standard

- Application

- Industrial, Chemical, Petrochemical, Water Treatment, Oil & Gas

- Design Standard

- API 6D / BS 5351

- Blowout Proof Stem

- Yes

- Operation

- Lever Operated

- Ball Material

- Stainless Steel / Hard Chrome Plated

- Fire Safe Feature

- Available

- Testing Standard

- API 598

- Body Material

- WCB (ASTM A216)

- Seat Material

- PTFE / RPTFE / Metal

- Face to Face

- ASME B16.10

About C.S. (W.C.B.) Three Piece Flanged End /Screwed End

Experience the acclaimed performance of the C.S. (W.C.B.) Three Piece Flanged End/Screwed End ball valve, distinguished by top-rated reliability across demanding industrial sectors. This dominant solution has garnered favorable reviews due to its dazzling operational efficiency and soaring durability. Crafted with a robust WCB (ASTM A216) body and advanced seating options PTFE, RPTFE, or Metal it ensures optimal sealing with stainless steel or hard chrome-plated ball. Meeting API 6D, BS 5351, and API 598 standards, it guarantees fire-safe, blowout-proof functionality and supports full-bore, two-way operations. Available in both flanged and screwed end connections, it excels in chemical, petrochemical, and water treatment plant uses.

Enhanced Features & Versatile Plant Applications

This three-piece ball valve stands out with a full bore design, two-way channels, and fire-safe construction, making it suitable for water, oil, gas, or steam. With an operating temperature tolerance up to 425C and a pressure range of 150 to 600 lbs, it adapts seamlessly to industrial, chemical, petrochemical, and water treatment plants. Its manual operation suits diverse usage types, ensuring precise flow control and safety for various industrial processes.

Certified Supply & Seamless Delivery Options

Certified to international standards including API 6D, BS 5351, and ASME B16.10, this valve assures compliance and quality. Exporters and traders from India can expect flexible payment terms. Main domestic market supply is favored with prompt freight handling and efficient drop-off services, enabled by a broad distribution network. Custom solutions and reliable delivery make this valve a preferred choice for industrial applications requiring high standards.

Enhanced Features & Versatile Plant Applications

This three-piece ball valve stands out with a full bore design, two-way channels, and fire-safe construction, making it suitable for water, oil, gas, or steam. With an operating temperature tolerance up to 425C and a pressure range of 150 to 600 lbs, it adapts seamlessly to industrial, chemical, petrochemical, and water treatment plants. Its manual operation suits diverse usage types, ensuring precise flow control and safety for various industrial processes.

Certified Supply & Seamless Delivery Options

Certified to international standards including API 6D, BS 5351, and ASME B16.10, this valve assures compliance and quality. Exporters and traders from India can expect flexible payment terms. Main domestic market supply is favored with prompt freight handling and efficient drop-off services, enabled by a broad distribution network. Custom solutions and reliable delivery make this valve a preferred choice for industrial applications requiring high standards.

FAQs of C.S. (W.C.B.) Three Piece Flanged End /Screwed End:

Q: How does the C.S. (W.C.B.) Three Piece Flanged End/Screwed End valve ensure safety?

A: The valve features fire-safe designs and a blowout-proof stem, ensuring operational safety in high-risk environments such as chemical, petrochemical, and oil & gas plants.Q: What certifications apply to this valve for quality assurance?

A: It is manufactured in compliance with API 6D, BS 5351, ASME B16.10, API 598, and ANSI B16.5, ensuring international quality and safety standards are continuously met.Q: Where can this valve be used effectively?

A: It is ideal for industrial, chemical, petrochemical, oil & gas, and water treatment applications due to its robust construction and high-performance specifications.Q: What is the main benefit of using a full bore ball valve in industrial systems?

A: Full bore design allows for minimal flow resistance, maximizing efficiency and minimizing pressure drop, which is crucial for demanding process applications.Q: How is the valve installed in different pipeline systems?

A: The product is offered in both flanged end and screwed end (BSP/NPT) variants, allowing straightforward installation in diverse pipeline configurations.Q: What is the temperature and pressure range supported by this valve?

A: It supports media temperatures of up to 425C and pressure ratings of Class 150/300/600 lbs, accommodating extreme process requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ball Valves Category

ROTOR MIXING AND SHUNT VALVES

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection : Flanged / Threaded

Media : Other, Water / Hot Water / Steam

Application : HVAC Mixing & Shunt Systems

Finish : Epoxy Coated / Painted

Shunt Valves for Domestic Boilers

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Connection : Threaded / Flanged

Media : Other, Water / Steam

Application : Domestic Heating Boilers

Finish : Nickel Plated / Brass Finish

Brass Ball Valve F/F 'T Handle

Connection : Female x Female (F/F)

Media : Other, Water, Gas, Oil, Air

Application : Plumbing, Industrial, Water Supply, Gas Line

Finish : Chrome Plated

Send Inquiry

Send Inquiry