C.I. Two Piece Flanged End

C.I. Two Piece Flanged End Specification

- Pressure

- Up to PN 16

- Structure

- Two Piece

- Caliber

- Standard

- Channels

- Single

- Connection

- Flanged End

- Material

- Cast Iron (C.I.)

- Power

- Manual

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- Up to 120C

- Port Size

- 50mm to 300mm

- Flange

- IS:1538 / DIN / ANSI Standard

- Finish

- Painted / Epoxy Coated

- Application

- Industrial Pipeline, Water Supply, Irrigation, Chemical Processing

About C.I. Two Piece Flanged End

Versatile Use and Robust Performance

The C.I. Two Piece Flanged End is engineered for both handwheel and gear operation, adaptable for Direction Of Use in horizontal or vertical positions. Its usage type spans industrial pipelines, water supply, irrigation, and chemical processing. With its standard caliber and single channel structure, it shines in diverse sectors. The versatile flange design easily integrates with IS:1538/DIN/ANSI standards, extending its application beyond conventional boundaries and ensuring seamless pipeline integration.

Efficient Supply, Secure Packing, Broad Export Reach

We maintain prominent supply ability for the C.I. Two Piece Flanged End, assuring swift Packing & Dispatch and reliable shipment. These valves are shipped globally with a focus on safe packaging and timely dispatching. Payment terms remain flexible to accommodate varied client needs. With thriving export markets in Asia, Europe, Middle East, and Africa, our valves consistently meet the demands of distributors, exporters, and industrial end-users, supporting seamless international trade.

FAQs of C.I. Two Piece Flanged End:

Q: How can the C.I. Two Piece Flanged End valve be installed in a pipeline system?

A: This valve supports flexible mounting, allowing installation in either vertical or horizontal orientations. Simply align the flanged end with the corresponding pipeline flange and secure it according to industrial flange standards (IS:1538, DIN, or ANSI) for a leak-proof connection.Q: What media can be used with this valve?

A: The C.I. Two Piece Flanged End is designed for robust service with water, oil, gas, and steam, operating efficiently at temperatures up to 120C and pressures up to PN 16, making it highly versatile for multiple industrial applications.Q: When should the valves seat material be selected as rubber or metal?

A: Rubber seats are ideal where tight sealing and Class VI leakage prevention are required, particularly for water or non-corrosive applications. Metal seats are recommended for higher temperature, abrasive, or chemically aggressive media, ensuring longevity.Q: Where are these valves commonly used?

A: These valves are widely used in industrial pipelines, water supply systems, irrigation setups, and chemical processing plants due to their excellent corrosion resistance, adaptability, and reliability.Q: What is the process for packing and dispatching the valve?

A: Each valve undergoes strict quality checks, followed by protective packing to prevent transit damage. Valves are then dispatched according to client specifications and securely shipped for on-time delivery worldwide.Q: What are the main benefits of using this two piece design?

A: The two piece construction simplifies maintenance, ensures superior flow with a full bore design, and allows easy inspection or replacement of parts, making it advantageous for long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

P.P. Three Piece Screwed End / Flanged End

Price 50 INR / Unit

Minimum Order Quantity : 10 Units

Power : Manual

Pressure : Other, Up to 10 kg/cm

Finish : Smooth / Standard

Material : Other, Polypropylene (P.P.)

C.I. Butterfly Valve

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Manual

Pressure : Other, PN 1.0 & PN 1.6

Finish : Epoxy Powder Coated

Material : Other, Cast Iron (C.I.)

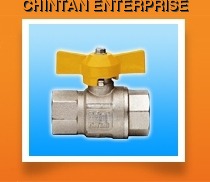

Gas Ball Valve F/F T Handle

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Manual

Pressure : Other, PN25 (25 Bar)

Finish : Chrome Plated

Material : Brass

Series 3000 Mixing and Deviating Valves

Price 100-300000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Pneumatic / Electric / Manual

Pressure : Other, PN16/PN25/PN40

Finish : Epoxy Painted / Polished

Material : Other, Cast Iron / Cast Steel / Stainless Steel

Send Inquiry

Send Inquiry